2009

| Low-Cost Swarm Robotics Platform |

Oct 2009 - Dec 2009 |

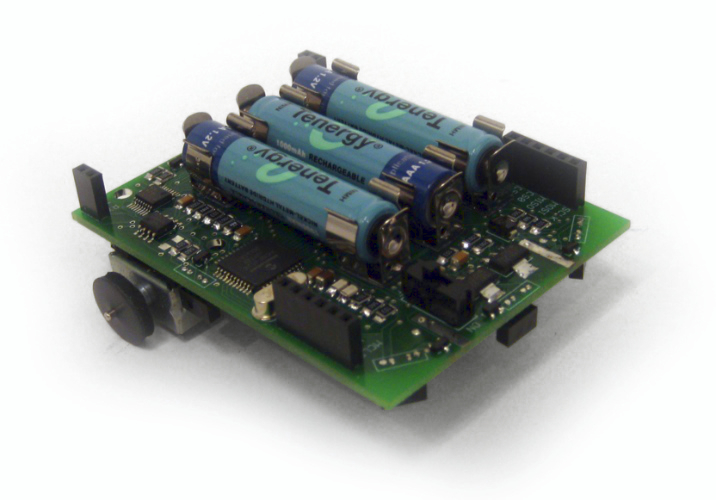

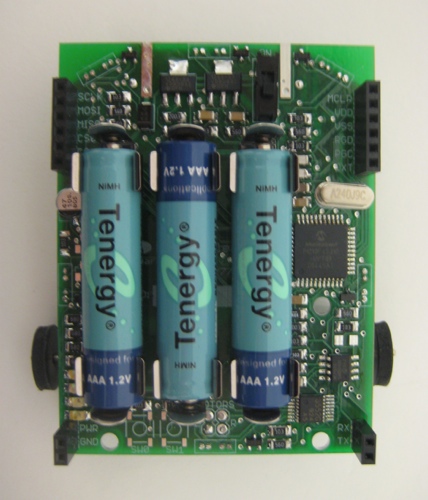

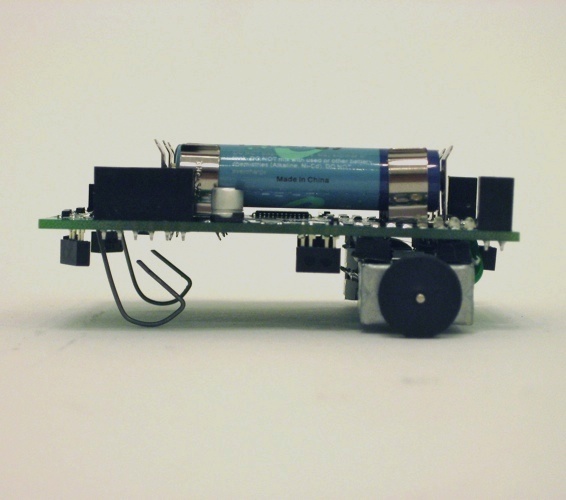

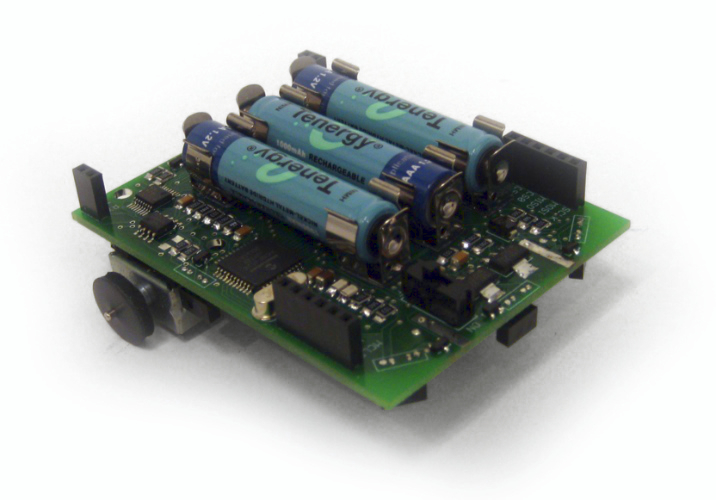

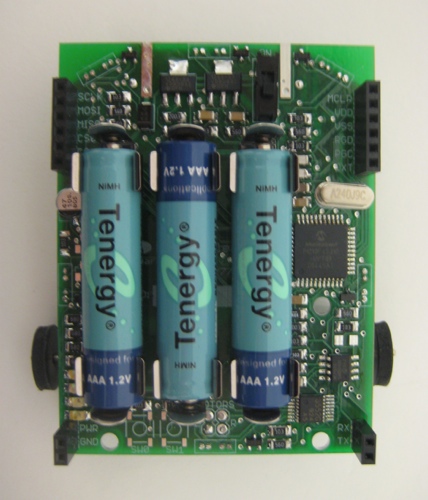

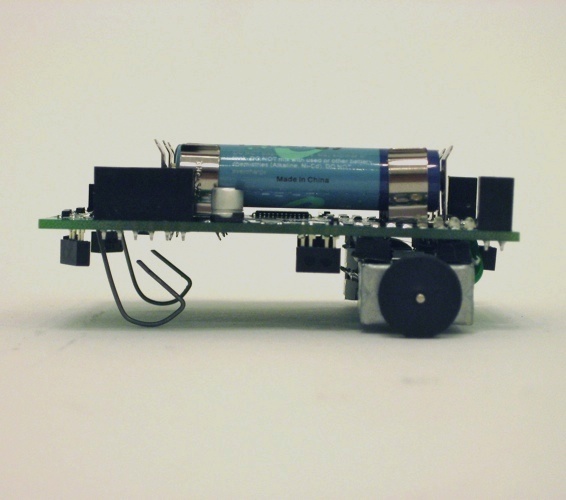

As a research project under the supervision of Dr. Gill

Pratt, I designed and fabricated a low-cost, expandable

robotics platform for use in research and education. This

included circuit design, component selection, PCB layout,

and system integration. The robot featured a 12 MIPS

processor, infrared communication and obstacle detection,

motor feedback, LED indicators, and an expansion port. The

final design had a component cost under $20, making it one

of the least expensive programmable mobile robots available.

final, assembled robot

|

top view

|

side view

|

|

Daniel Grieneisen, Jacob Izraelivitz, Nicholas Hobbs, Dr. Gill Pratt (faculty) |

| 3D Checkers Game |

Nov 2009 - Dec 2009 |

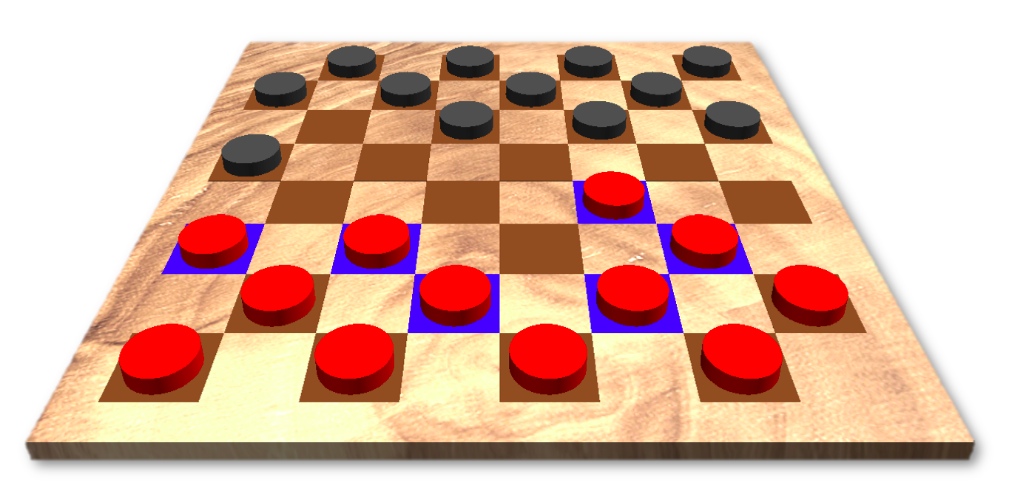

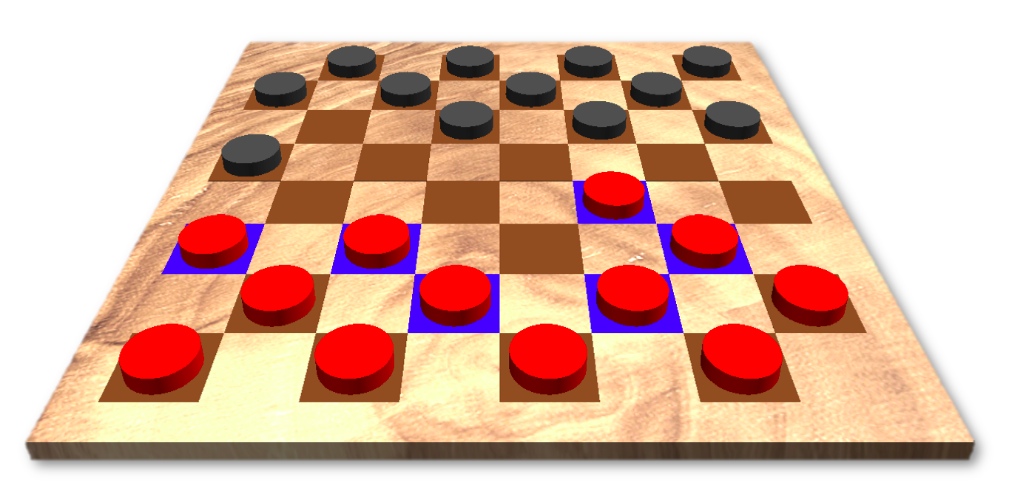

As a final project in my Software Design course, I worked

with two other students to create a 3-dimensional checkers

game in Python.

screenshot of the final interface

|

|

Xavier Ziemba, Sabrina Thompson |

| FPGA Breakout Arcade Game |

Dec 2009 |

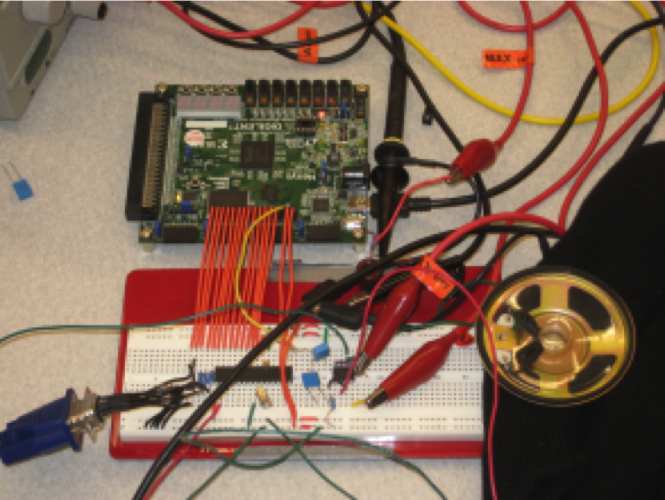

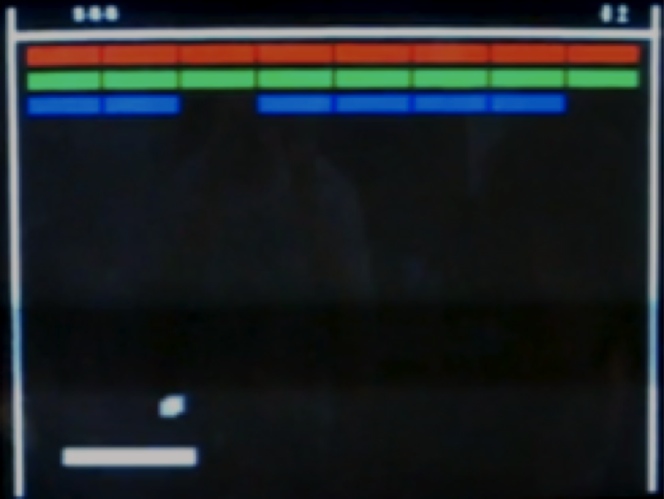

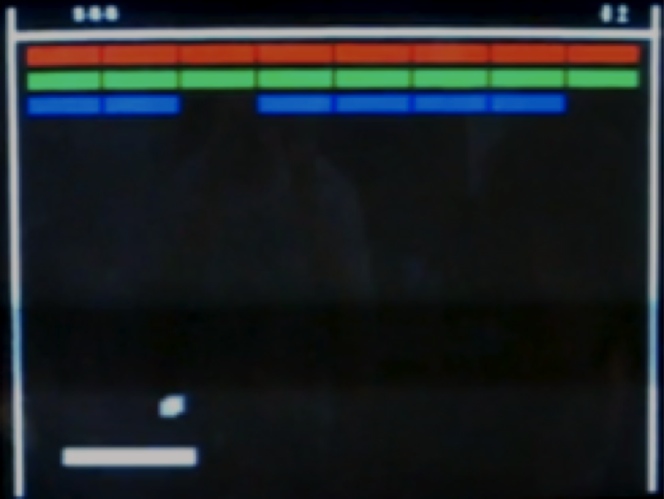

Inspired by the classic Atari arcade game, a few classmates

and I recreated the game Breakout in Verilog using a

Spartan-3 field-programmable gate array (FPGA) for our

Computer Architecture course. The system included a custom

input controller, and output mono sound and VGA video.

Atari Breakout arcade game (image source: The Arcade Flyer Archive)

|

FPGA game hardware

|

testing the game

|

VGA output

|

|

Daniel Grieneisen, John Watson, Lindsay Kaye |

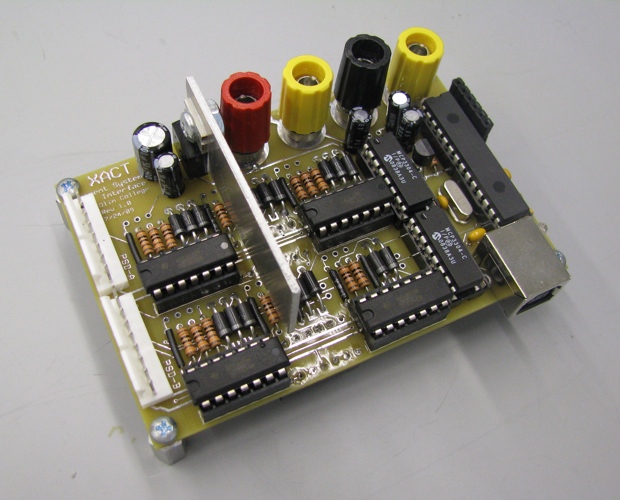

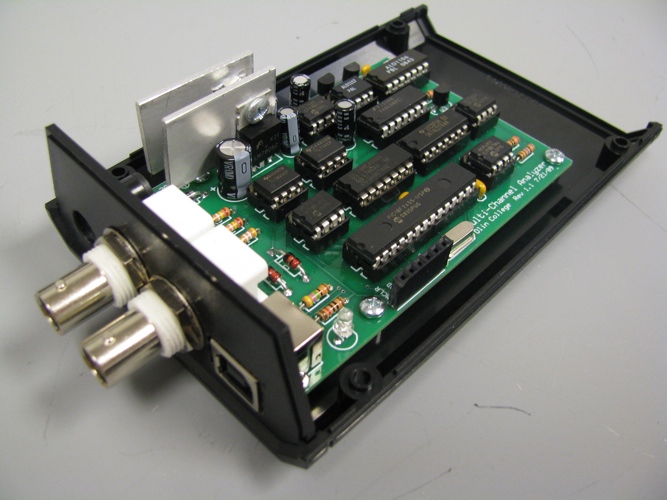

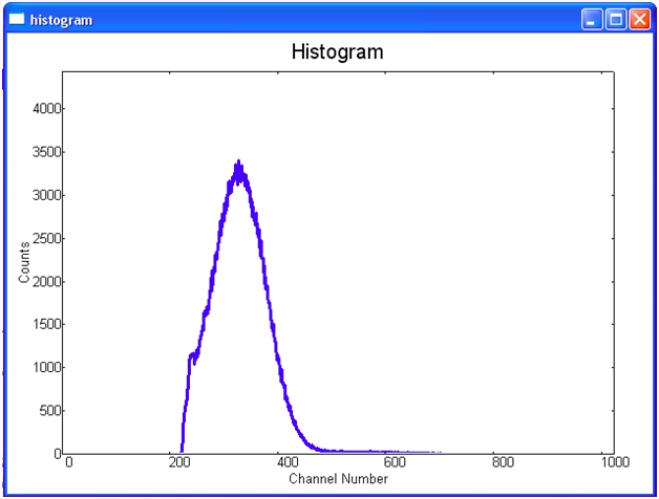

| USB Multichannel Analyzer |

Jun 2009 - Dec 2009 |

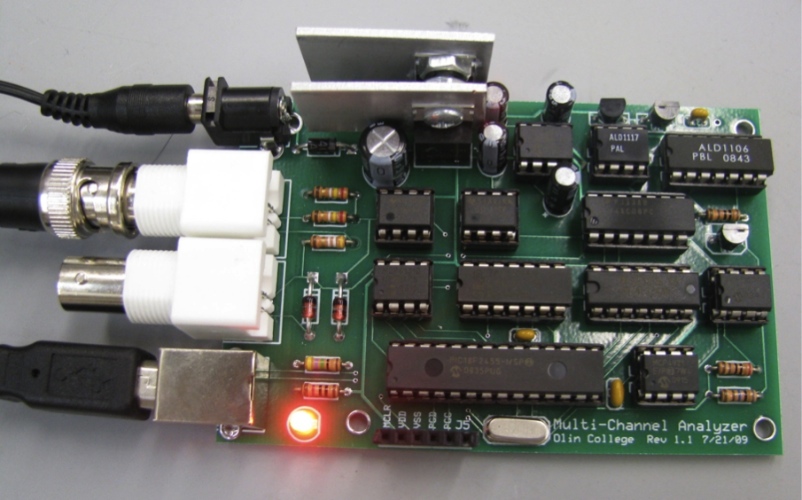

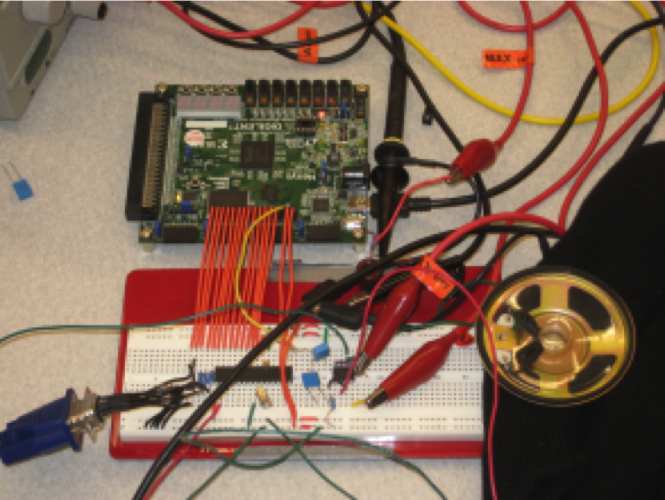

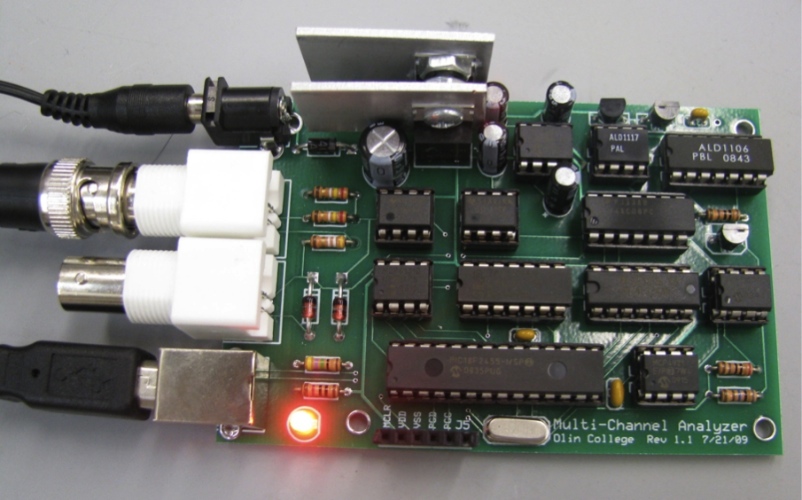

While working with the NASA / Olin Research Group

I designed, built, programmed, and tested a low-cost USB

multichannel analyzer (MCA) for use in NASA x-ray

spectrometry experiments. This included high speed circuit

design, component selection, PCB layout, and firmware

programming. Typical MCAs cost several thousand dollars; our design cost under $40

in components and provided the same functionality.

final hardware

|

NASA Goddard Space Flight Center (source: CTSI)

|

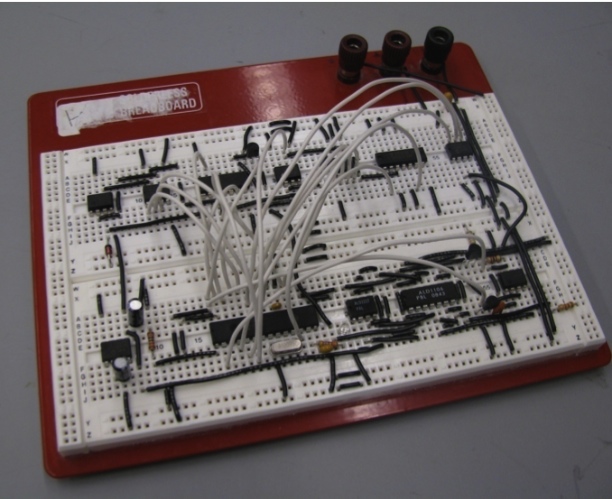

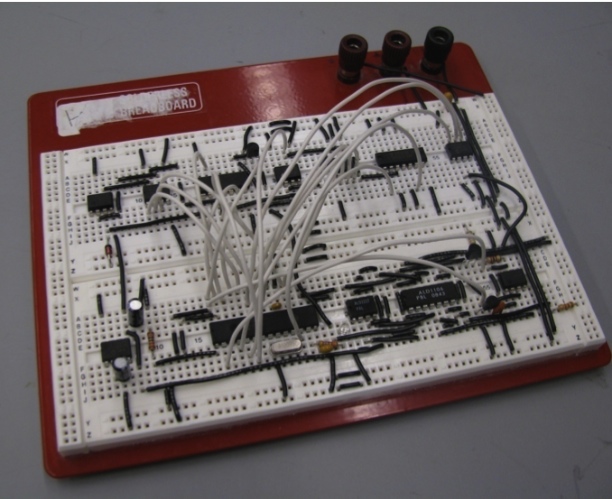

functional breadboard MCA

|

final hardware testing

|

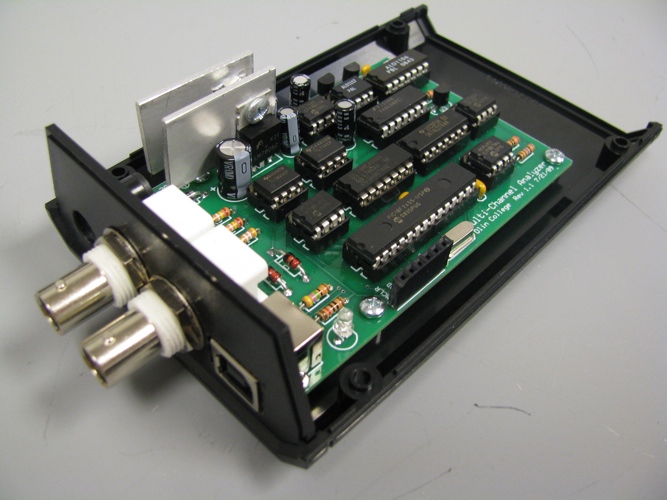

inside the case

|

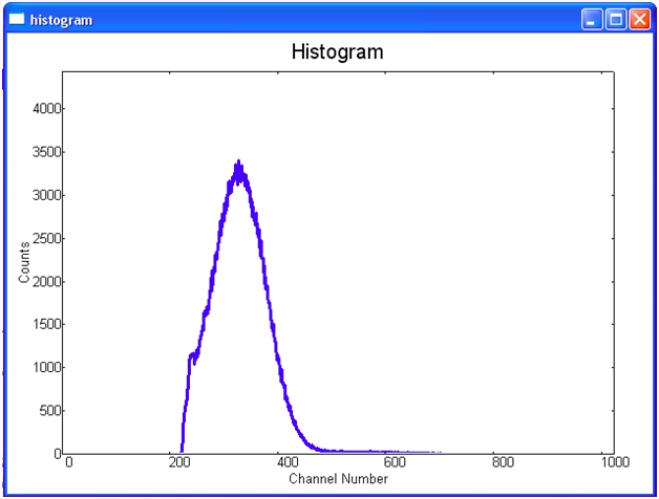

screenshot of GUI measuring 55Fe source

|

|

Sam Sun, Chen Wang, Dr. Stephen Holt (faculty), Dr. Bradley Minch (faculty) |

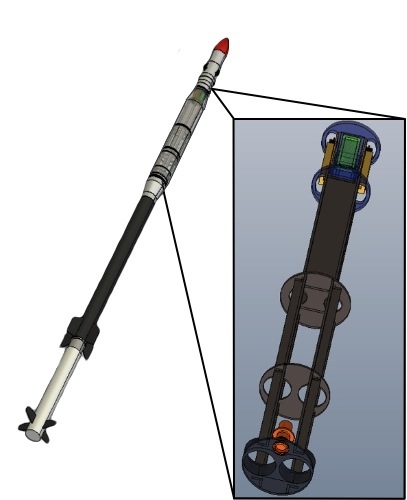

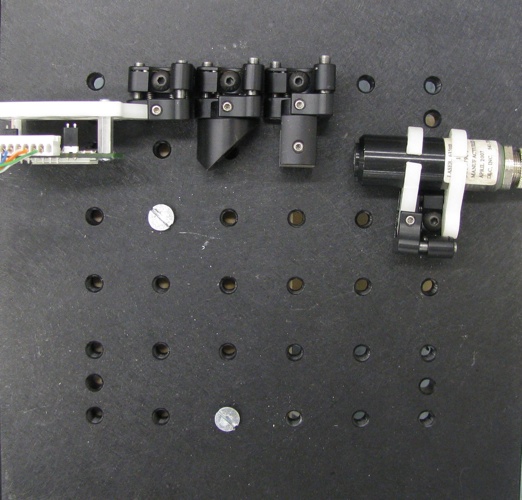

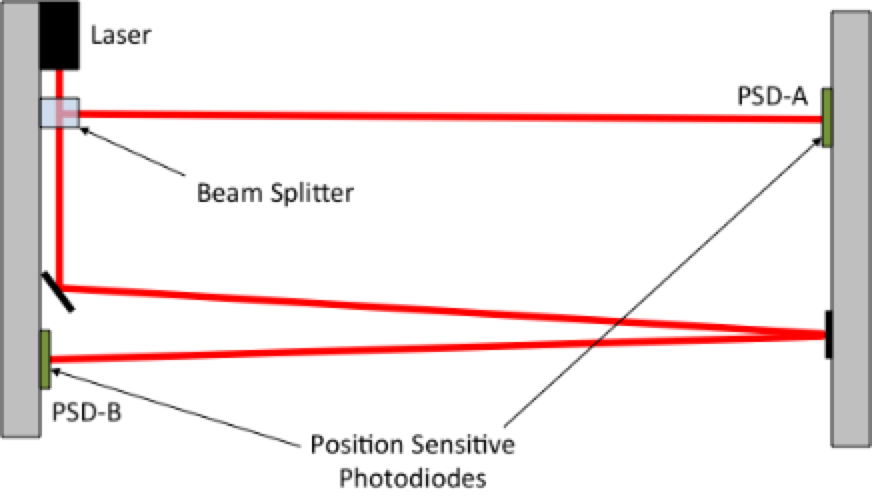

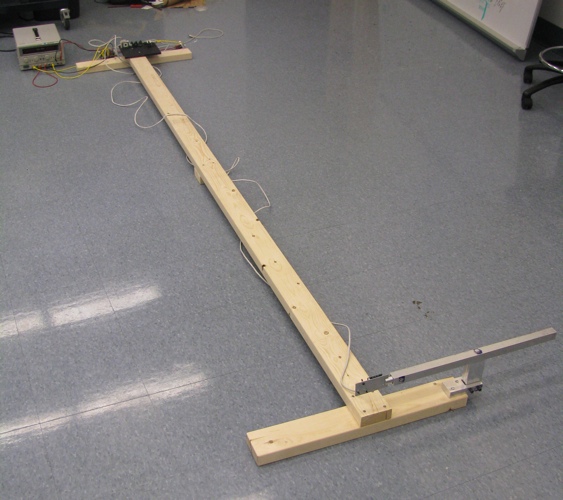

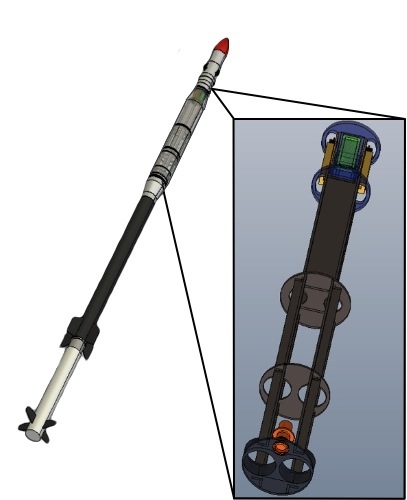

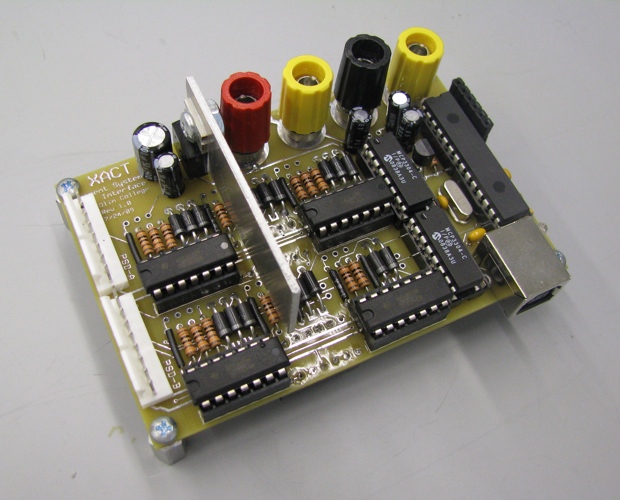

| Laser Alignment System |

Jun 2009 - Aug 2009 |

During the summer of 2009 as part of the

NASA / Olin Research Group,

I worked on a laser alignment

system for the X-Ray Advanced Concepts Testbed (XACT)

sounding rocket being developed at Goddard Space Flight

Center. My team designed and built a proof of concept system

capable of measuring extremely small tilts and lateral

displacements between the ends of the payload. These

measurements allow for corrections to be made to the

precision x-ray optics which may become misaligned due to

the stresses and vibrations of launch. For this project I

created custom test electronics in addition to aiding in the

overall design and testing.

model of XACT sounding rocket

|

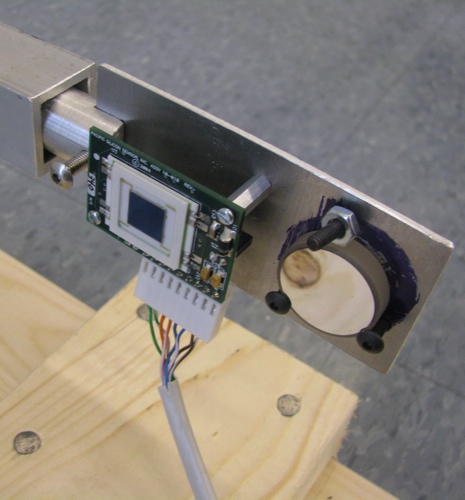

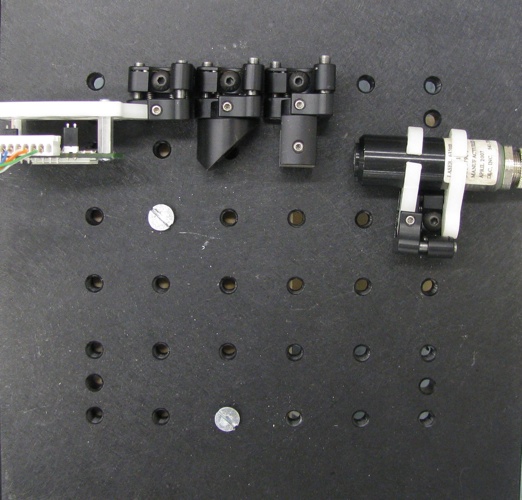

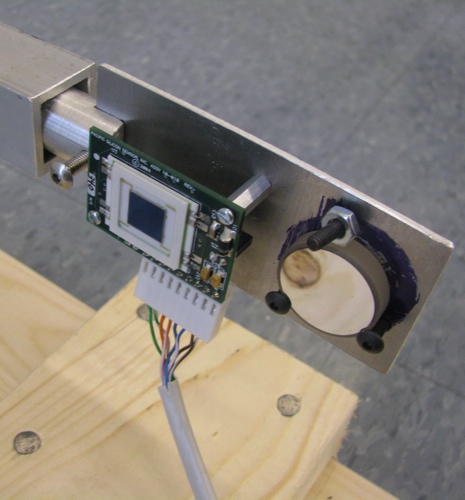

prototype electronics

|

test optics

|

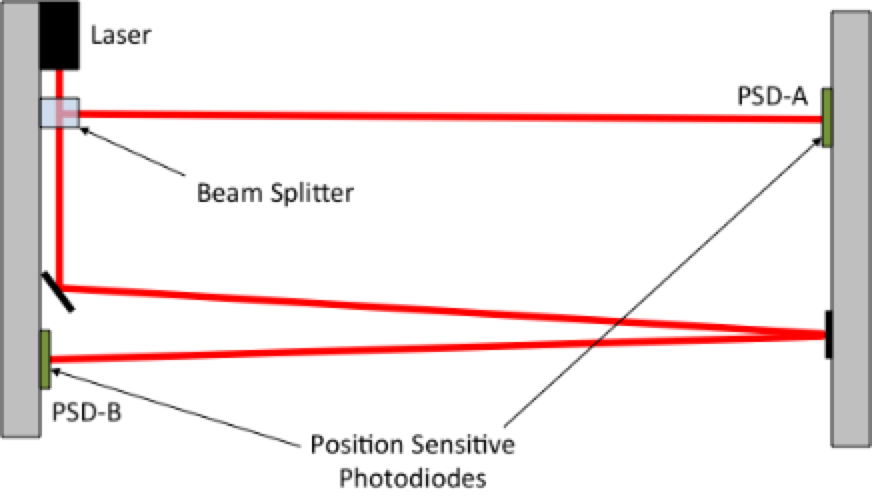

proposed system design

|

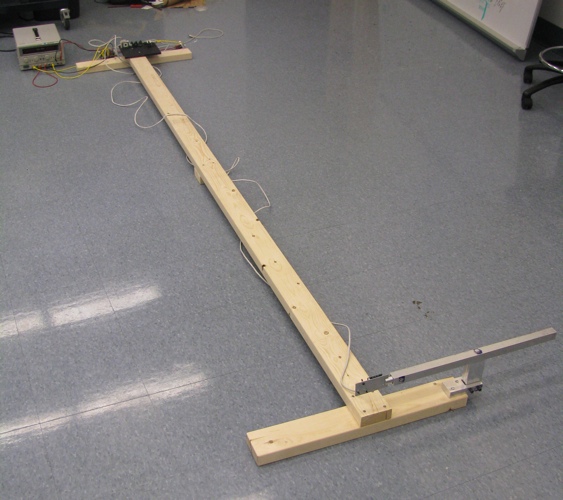

test rig

|

|

|

Clay Gimenez, Steven Higgins, Daniel Elg, Dr. Stephen Hold (faculty) |

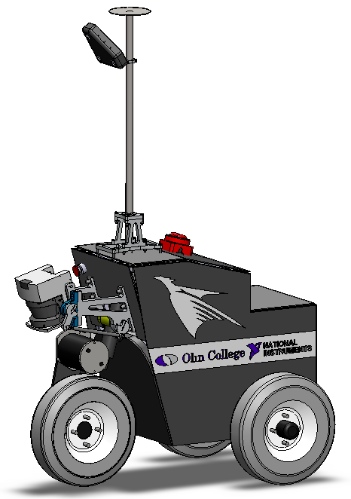

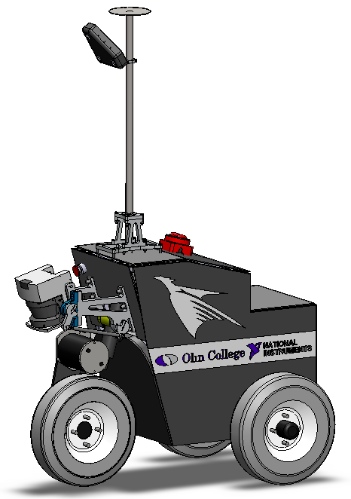

| Intelligent Ground Vehicle Competition |

Feb 2009 - Jun 2009 |

In the course of a single semester, four other sophomores and I designed, constructed,

programmed, tested, and competed a fully-autonomous off-road

vehicle that followed lanes, avoided obstacles, and

travelled to GPS waypoints. We placed second out of first-year teams at the

2009 International Ground Vehicle Competition (IGVC) in

Detroit.

engineering model of Brian, the 2009 Olin IGVC entry

|

building the robot over break

|

competition tent

|

Brian at competition

|

debugging at competition

|

|

Nicholas Hobbs, Daniel Grieneisen, Jacob Izraelivitz, Arash Ushani |

|

2nd out of first-year teams at the International Ground Vehicle Competition in Detroit, MI |

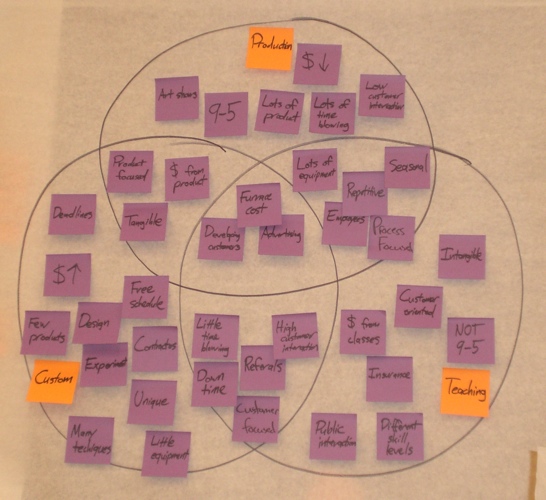

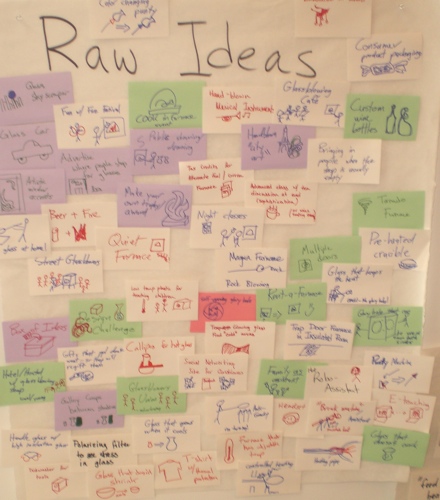

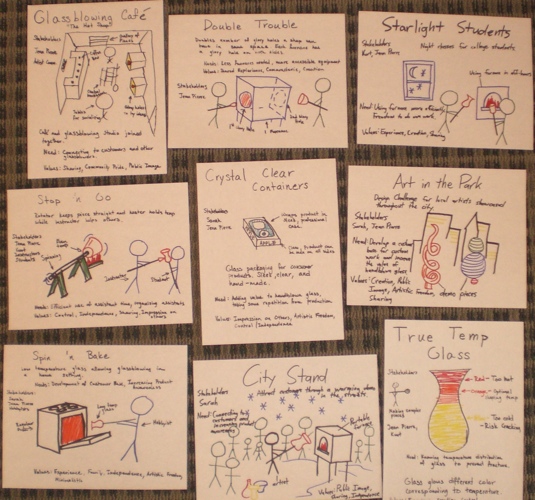

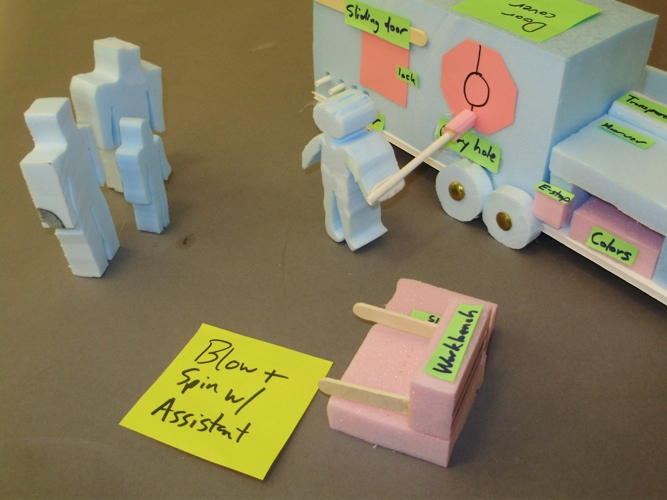

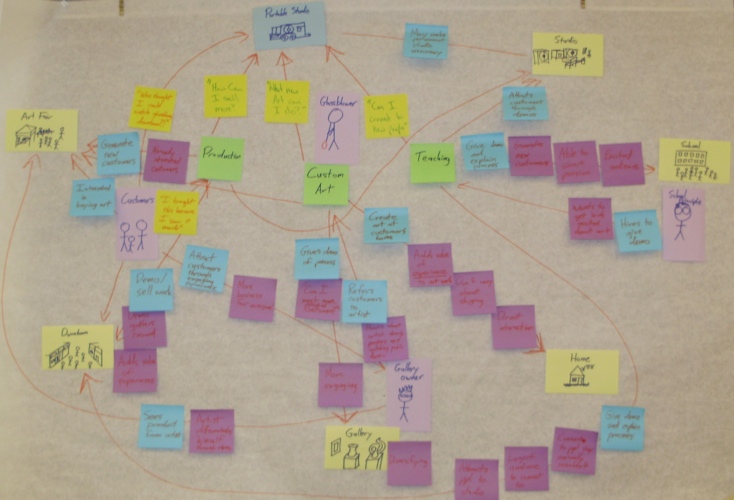

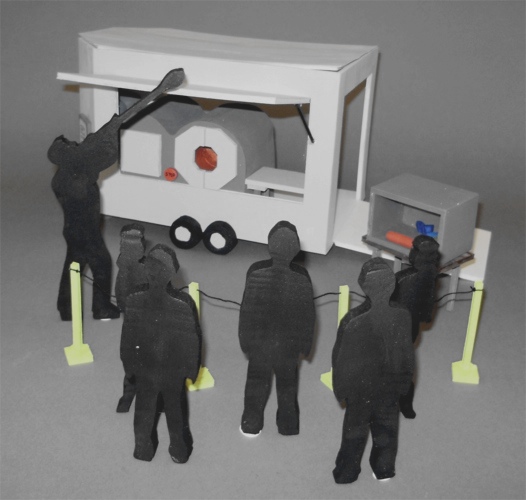

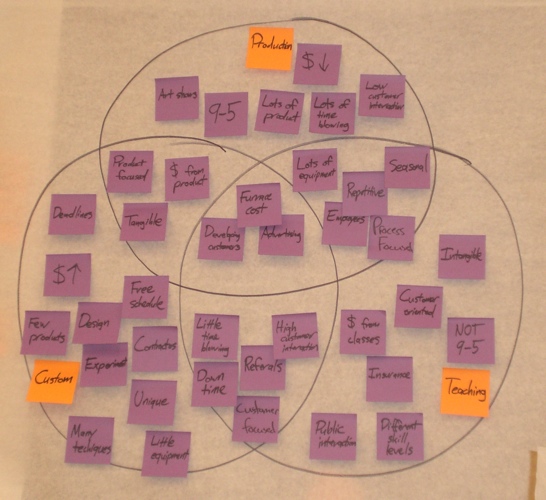

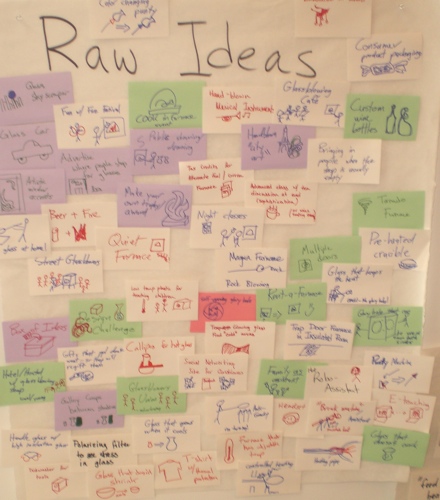

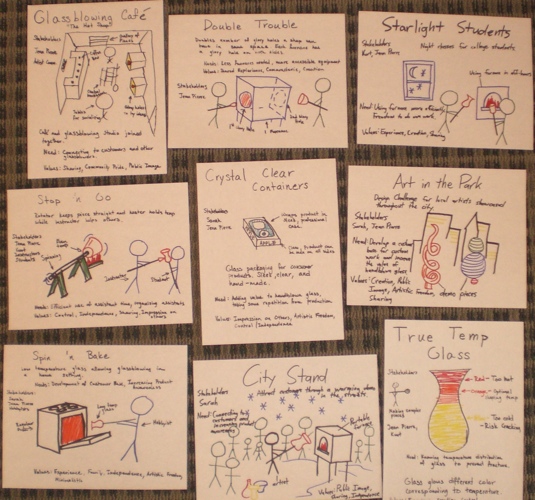

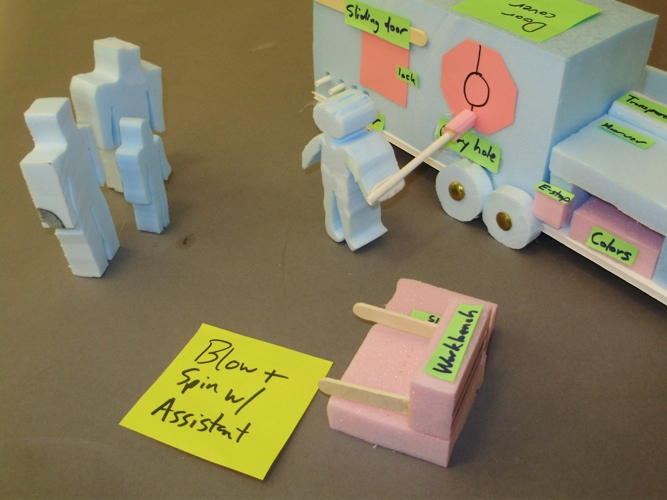

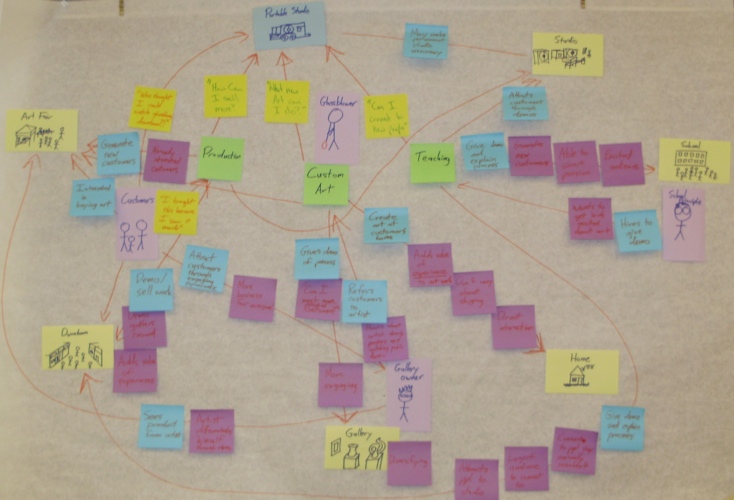

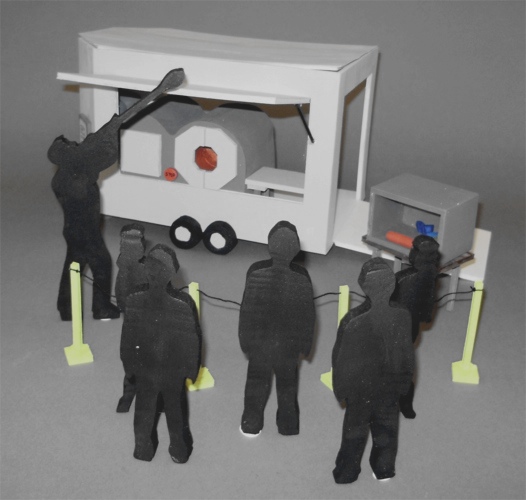

| User-Oriented Collaborative Design |

Feb 2009 - Apr 2009 |

As part of an extended design exercise in one of my classes, I worked with a group

of Boston glassblowers to design a novel product. I studied

glassblowers and their work, identified areas of opportunity,

generated ideas, led collaborative design exercises,

explored possible interfaces and interactions, and refined the ideas to

ultimately create a real-world solution to improve the lives of

these artists. Through this process, my team and I developed

a mobile studio that would allow glassblowers to connect to

customers in new and exciting ways.

model of mobile glassblowing studio

|

glassblower at work during user visit

|

glassblowing studio

|

initial observations and impressions

|

design exercises

|

brainstorming

|

gallery sketches

|

initial model

|

interaction map

|

model of portable studio

|

public demonstration

|

packed trailer

|

|

Neil Paulson, Velin Dimitrov |

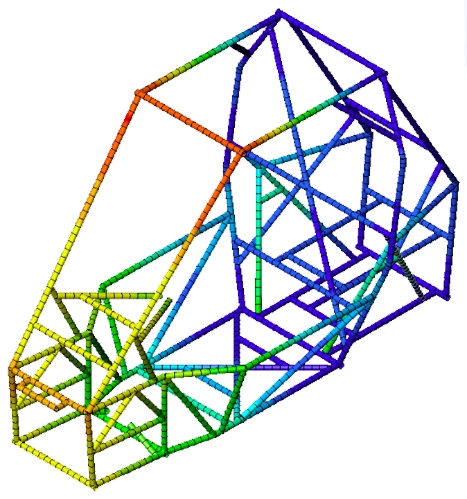

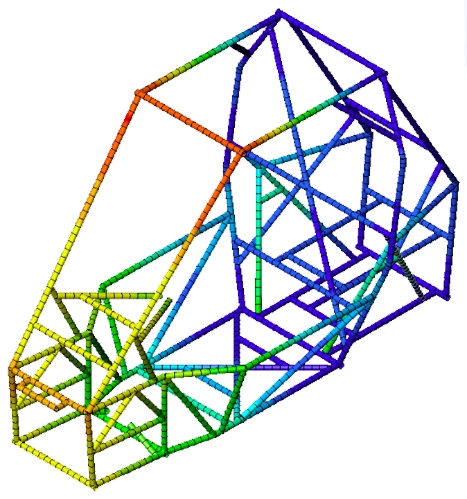

| Baja SAE Autimotive Design |

Oct 2007 - Dec 2009 |

Interested by the inner workings of cars, I joined the

Olin College Phoenix Racing team.

Along with a team of other engineering students, we designed

and built an off-road vehicle in our spare time to compete

in the SAE Mini Baja competition. As part of the team

charged with designing the chassis, I helped design a

rules-compliant frame and performed a series of structural

engineering tests (finite element analysis). I further

helped with machining and designing the electrical system.

finite element analysis of 2008 chassis

|

vehicle during testing

|

team at competition

|

final adjustments

|

vehicle at competition

|

|

team of 20+ students |

previous year | timeline | next year